tcp seal salt spray tests 2024|989178 : ODM Performances of the TCP coating Salt spray Salt Spray is used as an accelerated corrosion simulation; a sample of 12,5 x 7,5 cm fails when it present 3 pits or more. TCP without post-treatment failed the test after 96 H of exposure while the TCP with the post-treatment had a mean corrosion resistance of 360 hours on an aluminum 2024-T3. Resultado da 8 linhas · DLL-Helper é um site que oferece arquivos dll para baixar e .

{plog:ftitle_list}

web98k 100% 6min - 1080p. Rosa de catanduva gozando muito. 114.2k 100% 45sec - 360p. , delícia , fortaleza , puta , Meireles , 39.2k 99% 34sec - 720p.

Salt Spray is used as an accelerated corrosion simulation; a sample of 12,5 x 7,5 cm fails when it present 3 pits or more. TCP without post-treatment failed the test after 96 H of exposure while .• Slow corrosion in prototypic tests (e. g. salt spray, rooftop, etc.) • Provides adhesion for organic Coating such as paint • Helps prevent corrosion of painted surface • Conductive • Thin . The brand's Sea Salt Spray has a simple formulation—13 total ingredients that start with water and sea salt, and add glycerin, amaranth, and hydrolyzed rice protein—to add fullness in addition .Performances of the TCP coating Salt spray Salt Spray is used as an accelerated corrosion simulation; a sample of 12,5 x 7,5 cm fails when it present 3 pits or more. TCP without post-treatment failed the test after 96 H of exposure while the TCP with the post-treatment had a mean corrosion resistance of 360 hours on an aluminum 2024-T3.

Trivalent Chromium Conversion Coating for Corrosion

989178

Published: July 18, 2024 — Thursday Here’s the link to a safer salt (which we are also testing independently): https://amzn.to/3Sfm8r0. The Redmond Real Salt Ancient Sea Salt (“Mined in America”) pictured in this article tested positive for . This process helps predict the lifespan of coatings and materials when exposed to salt spray or sea water. Types of Salt Spray Chambers. Traditional Salt Spray Chambers: These are the most common and are used primarily for continuous salt spray tests as per ASTM B117. They help evaluate the corrosion resistance of electroplated layers and anti . Portion of the corroded area of uncoated AA 2024 and PDMSU-coated AA 2024 exposed to the salt spray test (ASTM B117). . Since the PEO coating is mainly composed of mineral oxides combined with hydroxyl groups, it is possible to seal it with silanization treatment [99]. For this reason, various studies have been carried out on the silane .

By Fineexpress / May 6, 2024 . Salt spray testing, also known as salt fog testing or salt corrosion testing, is a widely used method to evaluate the corrosion resistance of fasteners and other metal components. . Reporting: The results of the salt spray test, including the duration of exposure, the appearance of corrosion, and any other .

by salt-laden coastal applications. In fact, the salt spray . test is one of the most widespread and long-established corrosion tests; with ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus being the first inter - nationally recognized salt spray standard and originally published in 1939.This product is designed for chemical conversion, spray applications. CHEMEON TCP-HF Spray Bottle: CHEMEON TCP-HF chemistry optimized for small touch-up spray use. Packaged in a 16 oz spray bottle. CHEMEON TCP-HF Touch-Up Pen: CHEMEON TCP-HF chemistry optimized for touch-up and field repair use. Packaged in a 1.5 oz/60mL pen applicator. What percentage is a salt spray test? A salt spray test typically involves a solution of 5% sodium chloride (NaCl) in water. What is salt spray test as per ASTM B117? ASTM B117 is a standard test method for salt spray (fog) testing. It involves exposing test specimens to a controlled saltwater mist environment to assess their corrosion resistance.

hard drive test error code 0146

hard drive test error code 2000-0142

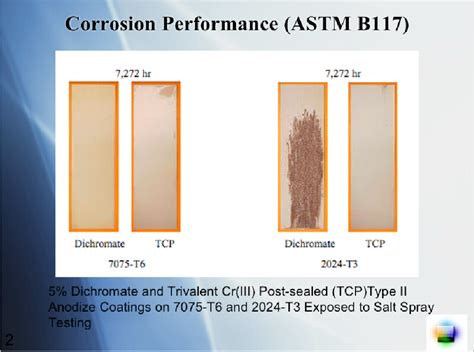

Among these, Al alloys such as 2024‐T3 (AA2024‐T3) and 7075-T6 (AA 7075-T6) . (TCP) is reported to consist of a mixture of hydroxides, . (pH = 3.8 temp = 40 °C). EIS and salt spray tests (100 h) suggested that sealing treatments efficiently improved the corrosion resistance and improvement was mainly explained by the self-healing . Seal immersion time is specified (23–28 min.) but. . a minimum of 200 mg/ft. 2 for 2024-T3 aluminum and. . Salt spray tests (ASTM B 117) are commonly run to evaluate the corrosion resistance . This post anodic oxidation process was performed by immersing samples in the electrolyte solution at 70 °C for 30 min. Immersion and salt spray tests show such a M-S sealing processing can result in much improved corrosion resistance. The M-S treated samples can resist 240 h of salt spray test without corrosion pitting. Salt spray test is a method to check corrosion resistance of coated samples. Watch the salt spray cabin test in this video! Facebook; Youtube; LinkedIn; . User Guide for Force Testing with Motorized Test Stand 9 February 2024 - 17:18. Accelerated Aging Tests: Explore the Compact UV Chamber for Small Spaces 1 February 2024 - 17:33.

Our technicians are trained to perform the salt spray test according to ISO 9227-2017 in one of our salt spray testing chambers. For example, salt spray testing is a paint industry test method, globally recognised. Continuous exposure to salt spray at 35 ° C +/- 2 ° C with a salt solution @ 5% +/- 1%. There are 3 main variants within the .

Introducing the latest edition of the highly respected standard, BS EN ISO 9227:2022+A1:2024, which focuses on corrosion tests in artificial atmospheres, specifically salt spray tests. This comprehensive document is an essential .The patented NAVAIR TCP process is simple to operate provided that attention is paid to the pretreatment and the pH of the bath. The normal operating pH range of this bath is 3.6 to 4.0. A lower pH may cause early corrosion in salt spray testing as the bath becomes more aggressive. A combination of lower pH and slightly elevated The search supports the following Boolean operators: AND, OR, NOT must be capitalized.. Search otherwise ignores capitalization for keywords. Use “” quotation marks to search for a phrase.. Phrase search matches all words in that order with nothing in between.

How To Conduct Salt Spray Test? Most salt spray testing instruments are user-friendly and easy to get started with. Following are the steps involved when a User or Tester intends to determine the corrosive properties of a specimen. Step 1: Place the sample inside the salt spray chamber and seal the ends.Corrosion tests in artificial atmospheres — Salt spray tests — Amendment 1: Footnote of Warning. . ISO 9227:2022/Amd 1:2024 Corrosion tests in artificial atmospheres — Salt spray tests Amendment 1: Footnote of Warning. Published (Edition 5, 2024) This amendment applies to ISO 9227:2022.Corrosion tests in artificial atmospheres — Salt spray tests. This document specifies the apparatus, the reagents and the procedure to be used in conducting the neutral salt spray (NSS), acetic acid salt spray (AASS) and copper-accelerated acetic acid salt spray (CASS) tests for assessment of the corrosion resistance of metallic materials, with or without permanent or .

The authoritative public forum for Metal Finishing since 1989 -----MIL-A-8625 Salt Spray Test Requirement on Type III Anodize? The latest change to MIL-A-8625 adds a requirement to the Table II Process Control Test section that says, "Type III coating shall be tested for corrosion resistance only when it is specified that the coating is sealed".

Salt Spray Test Standards and Regulations Salt spray testing adheres to various standards to ensure uniformity and reliability. ASTM B117: The most widely used standard for salt spray testing. . 25 Oct, 2024. Understanding the Importance of Inclined Impact Testing in Product Durability. 24 Oct, 2024.

Seal - if seal test fails check seal for silicate. Hope this is of use to you. Martin Trigg-Hogarth surface treatment shop - Stroud, Glos, England. Anodizing Thickness and Corrosion Tests. . We have carried our salt spray testing on 2024 and 7075 test specimen chromic acid anodize bath. The test specimen sealed in DI water Temp 96 °C, time .

Organic coatings applied to AnoChem TCP pass the adhesion test ASTM D 3359, ISO 2409, and Method 631 of MIL-STD-141. . Outperforms conventional chromate coatings in corrosion resistance testing on high copper bearing aluminum alloys 2024 and 2019 . Anoplate maintains its own in-house salt-spray test chamber and its own electric resistivity . Neutral salt-spray testing over a 7-day period revealed no significant differences in the stand-alone corrosion protection afforded to AA7075-T6, while the thin-layer mist test did serve to differentiate the TCP coating performance. .Salt Spray Test is operated by a sister company of PreTreat Ltd, a British-owned, independent company that formulates, fabricates and supplies a wide range of speciality chemicals for the manufacturing and metal finishing industries.. Founded in 2006, they have evolved to become one of the leading privately-owned speciality chemicals manufacturers in their field.

The easiest to do is hot water seal. Use distilled or demineralised water with a conductivity below 150 microsiemens and a pH of about 6 (5.5-6.5 is not uncommon). . If you spend some time searching the site you will find perennial statements from many people that salt spray testing of 2024 test panels usually says more about the quality of .

hard drive test error code 7

WEBJoyce Spaeth : r/AltarOfVenus. NSFW. Joyce Spaeth. 110. 0 comments. New. Add a Comment. More posts from r/AltarOfVenus. 80K subscribers. dirtybayarea. • 5 days ago. .

tcp seal salt spray tests 2024|989178